Near machine scrapped due to improper maintenance? Summer UV machine, photocopier maintenance secrets!

Release time:

2025-03-31

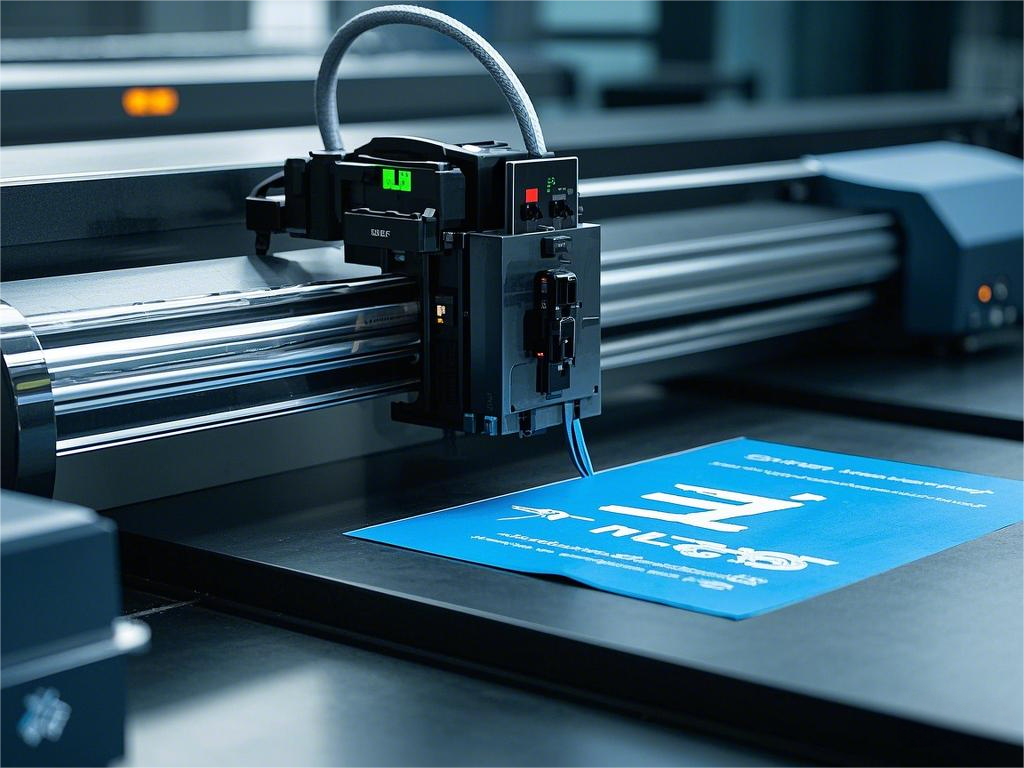

Recently, high-temperature warnings have been issued in many parts of China, with some areas exceeding 40℃, and the hot weather continues. In summer, with the rapid increase in temperature and humidity, not only do people need to protect themselves from the heat, but various printing equipment in our factories also need proper maintenance, otherwise the consequences will be too serious.

Recently, a colleague revealed that because they were rushing to complete an urgent order, they did not pay attention to cooling the large-format printer. Later, the printer frequently malfunctioned, first exhibiting ink flying and fuzziness, and finally the printer's control card had a major problem, causing circuit damage and nearly rendering it unusable.

The optimal working temperature for a large-format printer is 22-25 degrees Celsius. If cooling and dehumidification are not done well in summer, the impact on the large-format printer is enormous:

1. During operation, the large-format printer constantly emits heat. If ventilation and heat dissipation are not timely, the accumulation of heat can easily cause malfunctions in the printer's control boards. The data chips on the mainboard will affect data transmission, slowing down printing speed, or even causing more serious damage to other chips, electronic components, and circuits.

2. In high-temperature environments, ink fluidity is poor, easily leading to ink breaks, resulting in poor print quality and broken lines.

3. If a large-format printer is kept in a space with excessive humidity for a long time, it is prone to ink clogging. At the same time, delicate data chips and electronic components are easily corroded, affecting the service life of the printer. Therefore, the humidity in the machine room should be maintained between 35%-65%.

So, in the sweltering summer and under continuous high temperatures, how should large-format printers and UV printers be maintained? Here's a summary!

Large-Format Printer Summer Maintenance Tips

No.1

The optimal indoor temperature for operating a large-format printer is between 15-30℃. With temperatures often exceeding 35℃, using fans or air conditioning for cooling is necessary.

No.2

Dryness often accompanies high temperatures. At this time, it is necessary to prevent static electricity and dry ink. You can frequently sprinkle some water on the ground, which helps prevent the indoor air from being too dry. Simultaneously, install a grounding wire on the large-format printer to prevent static electricity.

No.3

In a high-temperature environment, do not connect too many devices to one power strip. The printer and computer can each have a dedicated power strip. Other electrical appliances such as chargers, fans, and air conditioners should use a separate power strip and not share one with the printer.

No.4

In southern China, summers are not only hot but also rainy. Excessive humidity affects the drying speed of the image. To avoid sticking during roll-up due to undried printing ink, the drying system's level can be adjusted to the maximum during machine operation. If necessary, add a cooling fan for drying.

No.5

During rainy summer weather, high humidity can affect the normal use of the large-format printer. A dehumidifier can be used to dehumidify. At the same time, the main body of the large-format printer should be covered to prevent humid air from affecting the circuit boards and components.

No.6

To ensure the stable and continuous operation of the large-format printer in summer, it is essential to strictly control indoor temperature and humidity (humidity is best controlled at 35%-65%). It is best to place a thermometer and hygrometer indoors for easy real-time viewing and timely adjustments.

UV Printer Summer Maintenance Tips

No.1

Temperature Control

In summer, high temperatures can affect use. It is recommended to control the indoor temperature. The UV printer should be placed in a cool, shaded corner to avoid high temperatures and direct sunlight. To ensure print quality, the indoor printing temperature in summer should be controlled at around 28℃, and the humidity should be 60%~80%. If the UV printer's working environment is too stuffy, install cooling equipment in the workshop.

No.2

Print Test

After turning on the UV printer every day, be sure to print a test strip first, turn on the white ink circulation, and check the nozzle status. In the summer, high temperatures can cause ink to evaporate easily, so pay attention to moisturizing and perform regular ink pressure maintenance daily.

No.3

Power Off and Moisturize

When the UV printer is not working for a long time, you can choose to power it off and moisturize it. Do not let the machine remain on standby, as this will increase the temperature.

No.4

Clean the Print Head Regularly

Clean the inside and outside of the UV printer weekly, especially in key areas such as the print head and rails. Maintaining cleanliness is essential. Regularly confirm that the surface of the transfer board plug is clean, and that the connection is tight and secure.

No.5

Pay Attention to Nozzle Maintenance

The nozzle is the core component of the UV printer and should be protected to the maximum extent.

1. Perform regular ink pressure maintenance daily.

When the UV printer is operating, due to color reasons, not every nozzle is working. After a long time, the nozzle surface dries out, the ink oxidizes and hardens, and under the irradiation of the curing lamp's residual light, this is a major cause of nozzle oblique spraying. Therefore, perform daily ink pressure maintenance. When the ink on the nozzle surface cannot be wiped off, immediately wipe it with cleaning solution to achieve the purpose of moisturizing.

2. Use high-quality ink from a regular ink manufacturer to reduce the risk of failure.

3. Pay attention to the water tank temperature. Summer temperatures are higher, so simultaneously monitor whether the antifreeze level in the water tank is above the standard line. You can also adjust the water tank temperature to 28-30 degrees. At the same time, observe the water tank heat dissipation; excessive dust in the water tank will affect the water tank's heat dissipation, causing the water tank compressor to malfunction.

RELATED INFORMATION

2025-03-20

Steps for shutting down large format printers (solvent, eco-solvent, UV) during holidays

Large format printers, photo printers, and UV printers are indispensable equipment in the modern advertising industry. Their maintenance and upkeep during holidays are particularly important. To ensure stable operation and extend their lifespan, the holiday shutdown procedure is crucial.

2025-03-20

What are the differences between UV printers, photo printers, and inkjet printers?

Many people are confused about the differences between UV printers, photo printers, and inkjet printers, often using the terms "plotter" or "inkjet printer" interchangeably. So, what exactly is a photo printer?

Customer Service Hotline

Address:No.95, Xihuan Road, Bailong Community, Chengnan Street, Jingzhou District, Jingzhou City, Hubei Province

WeChat Public

WeChat Public

Website construction:China Enterprise Power Yichang

This website already supports IPV4 / IPV6 bidirectional access